Safe Isolation Procedure – A Complete Guide

Safe isolation is imperative before carrying out any form of electrical alteration or addition. Failure to follow a recognised Safe Isolation Procedure can, and has, resulted in an Electric Shock, serious burns or even death.

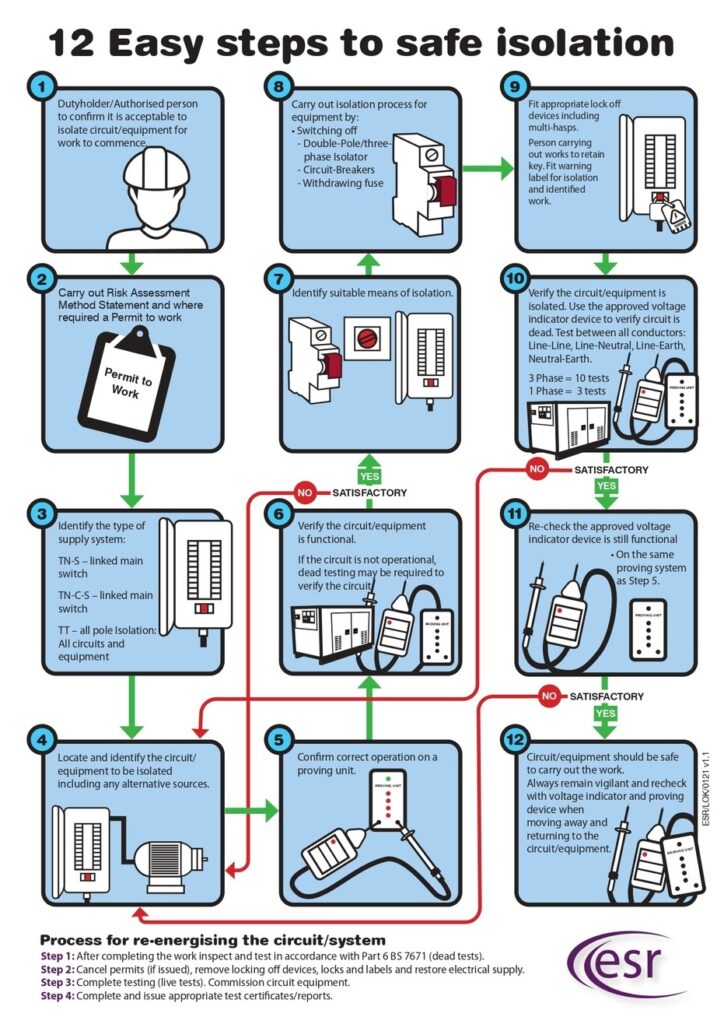

Safe Isolation Procedure

In brief…

- Identify the circuit to be isolated (including any alternative sources of supply).

- Identify a suitable means of isolation for the circuit(s), (including any alternative sources of supply).

- Confirm the correct operation of your approved proving unit (check the manufactures instructions).

- Ensure your approved voltage indicator is safe to use & visually inspect for damage.

- Confirm the correct operation of your approved voltage indicator test instrument using an approved proving unit.

- Confirm if the circuit to be isolated is functional (if not then dead testing maybe required to confirm the circuit).

- Isolate the circuit(s) and Lock Off.

- Verify the circuit(s) is/are isolated using your approved voltage indicator.

- Re-check the approved voltage indicator is still functioning (as per step 5).

- Once more verify the circuit(s) is/are isolated using your approved voltage indicator.

Safe Isolation Certificates

A safe isolation certificate can be issued upon the successful safe isolation of any electrical circuit or equipment, you can generate Electrical Isolation Certificates with our mobile app.

Electricity Kills

It only takes between 100 mA and 200 mA (0.1 to 0.2 amp) to be lethal.

Lock Off / Lock-Out Kits

The Electrical Safety Roundtable (ESR) proposes that the essential 6th item of PPE for all electrical workers should be a lock-off kit, to avoid the extreme risk of electrocution.

🔒 LOCK IT OFF – Electrical tape on the MCB is NOT locked off!

Check out these Amazon deals → Electrician’s Lock Off Kits.

Guidance on the management of electrical safety and safe isolation procedures.

Electrical Safety First Best Practice Guide 2 (Issue 3) – Guidance on the management of electrical safety and safe isolation procedures for low voltage installations.

The AC “Low Voltage” or “LV” band is from 50 volts up to 1000 volts.

The safe isolation of plant and equipment

The Health and Safety Executive (HSE) has published document HSG253 which provides guidance on how to isolate plant and equipment safely, and how to reduce the risk of releasing hazardous substances during intrusive activities such as maintenance and sampling operations.

It includes a methodology for selecting ‘baseline’ process isolation standards and outlines preventive and risk reduction measures.Lock-off kits are an essential part of an electricians tool kit, the ESR proposes Lock-Off Kits to be the sixth item of PPE.

The Law

Under the Health and Safety at Work Act, employees are required to co-operate with their employer to enable the requirements of the regulations to be met.

The Electricity at Work Regulations 1989 require that employees themselves comply with the regulations.

The Management of Health and Safety at Work Regulations 1999 require employers to make a suitable and sufficient assessment of the risks.

Sources:

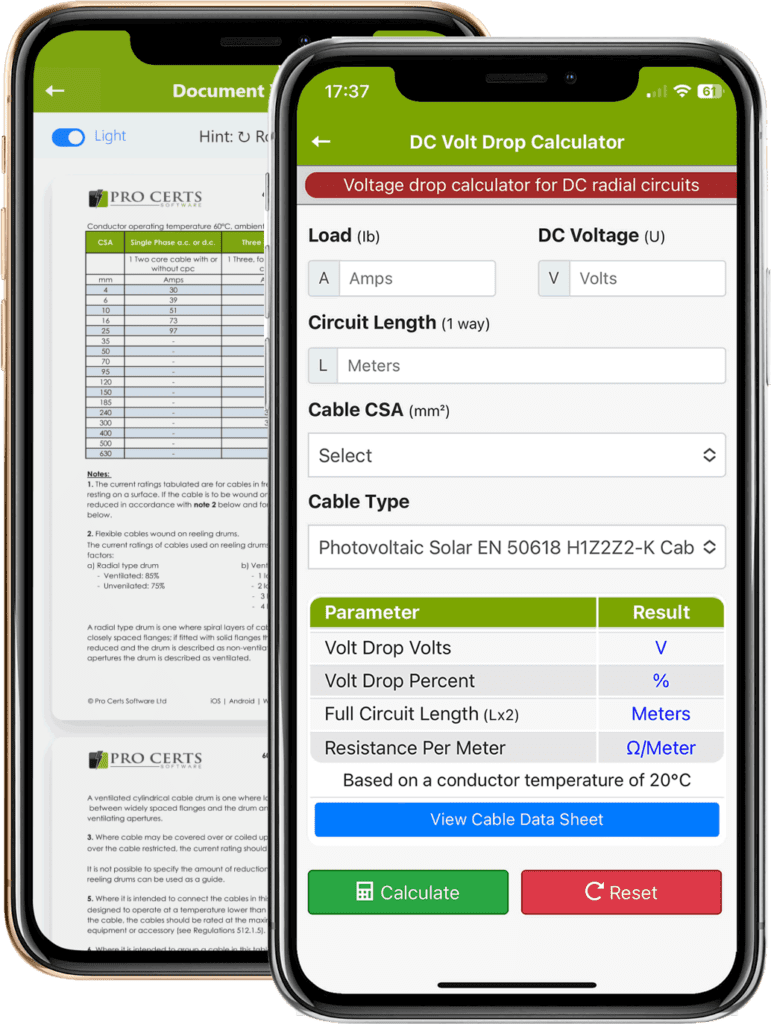

Download The App!

Electrical Tools & Reference, full to the brim with tables, charts, forms and calculators.

For further information visit The Electricians App.

Or, get the cloud desktop version →